HLOOP

Optimising AI and human cooperation in manufacturing

.jpg)

In Brief

- Challenge: Future Digital Challenge

- Challenge Type: National Challenge Fund

- Status: Active

The Challenge

Ireland has adopted artificial intelligence for process optimisation in manufacturing more slowly than expected. This is a missed opportunity so far because it could make the Irish manufacturing sector more competitive and sustainable. At the moment, AI solutions are being tailored for individual tools and contexts (used material, shape of the manufactured object). This means industry will need an unfeasible number of unique AI models.

The Solution

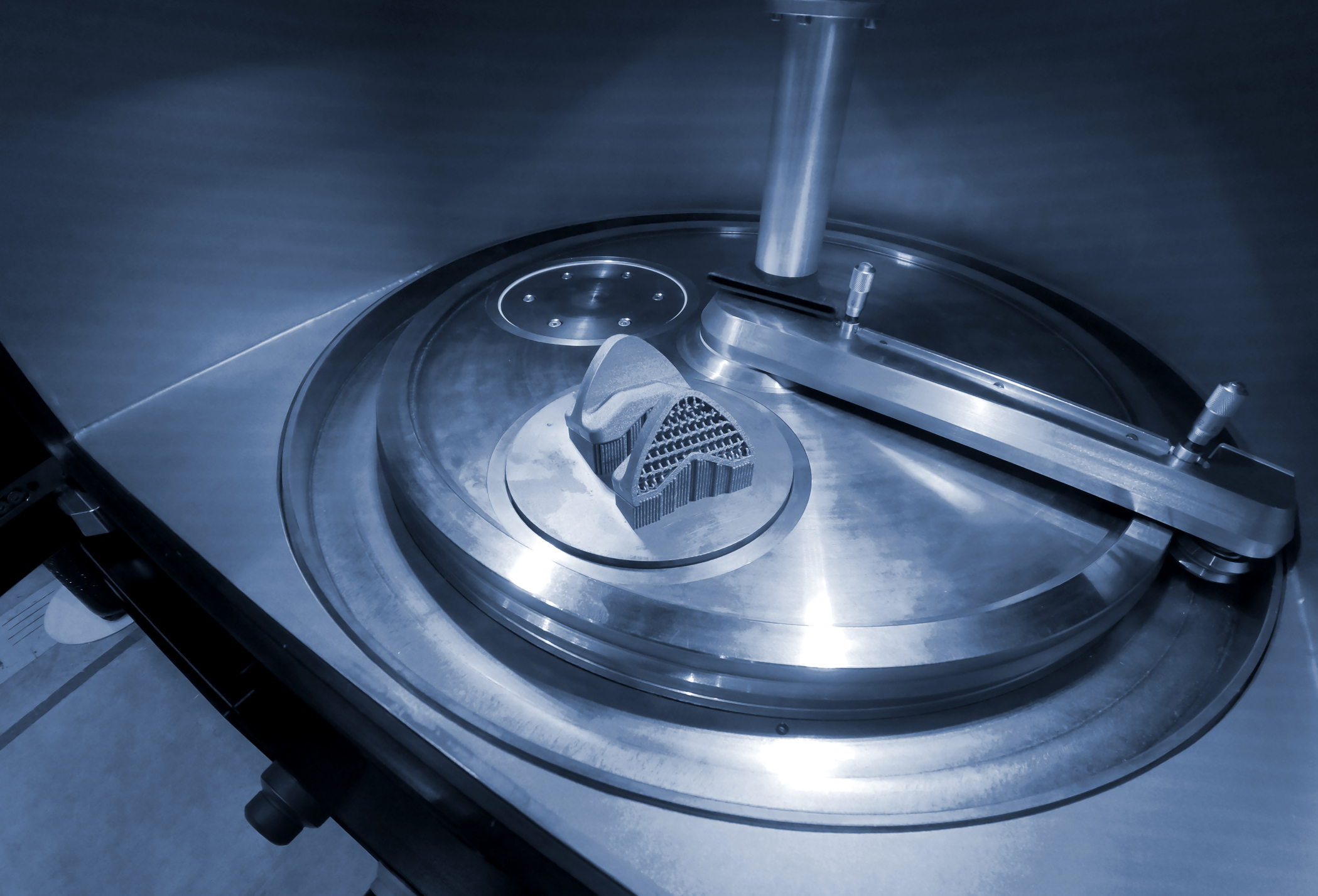

Instead of developing an AI-solution for each machine tool and context, HLOOP proposes to build a single AI model exploiting the synergy between AI and human workers. Assessing the quality of the manufacturing process is more effectively done by humans than AI, while AI is better at dealing with high-dimensional decision problems. We plan to use the feedback of machine operators to train on-the-fly (that is without using any pre-collected dataset), and in real time, an AI-model that can predict when the manufacturing process is good/bad, and then optimise it. To be successful, it must demonstrate explicit advantages in a complex manufacturing process. Laser Metal Additive Manufacturing, due to its complexity and greenness, will be the testing ground for HLOOP.

The Team

- Team Lead: Dr Alessio Benavoli, Trinity College Dublin

- Team Co-Lead: Prof. Rocco Lupoi, Trinity College Dublin

Societal Impact Champion

- Patrick Walsh, SchuF Valve technology